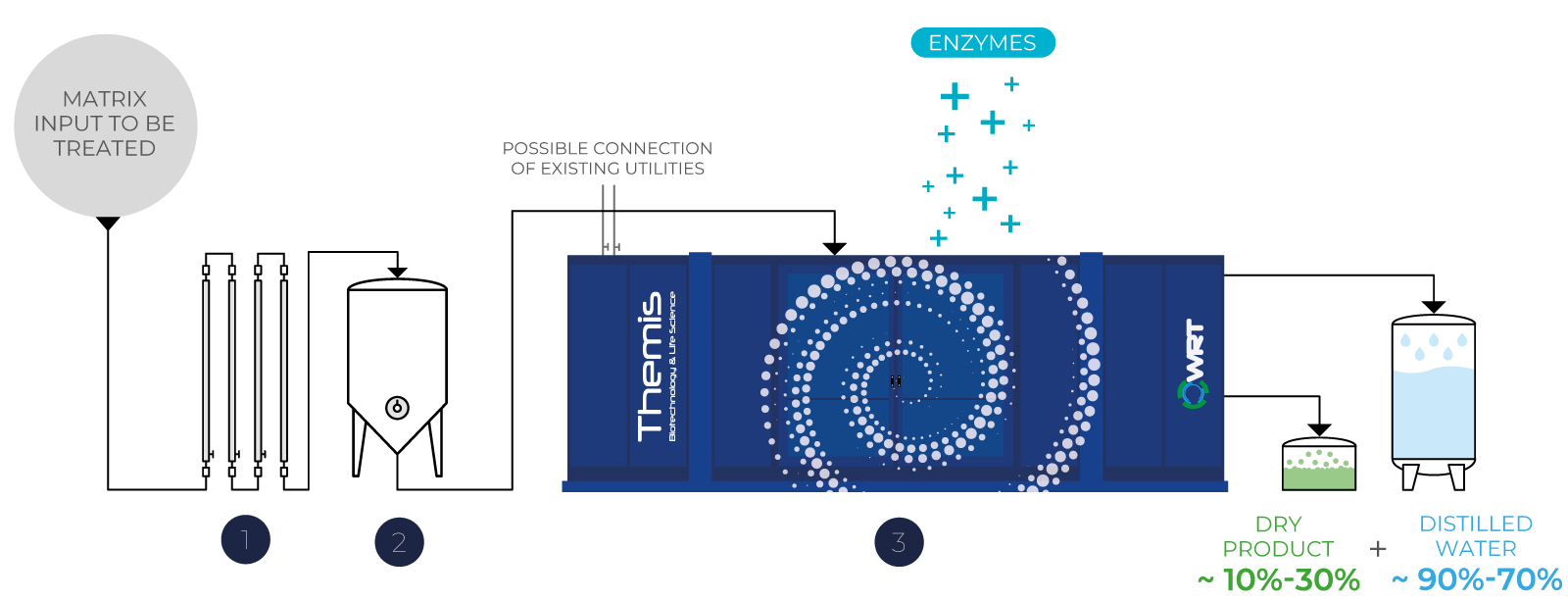

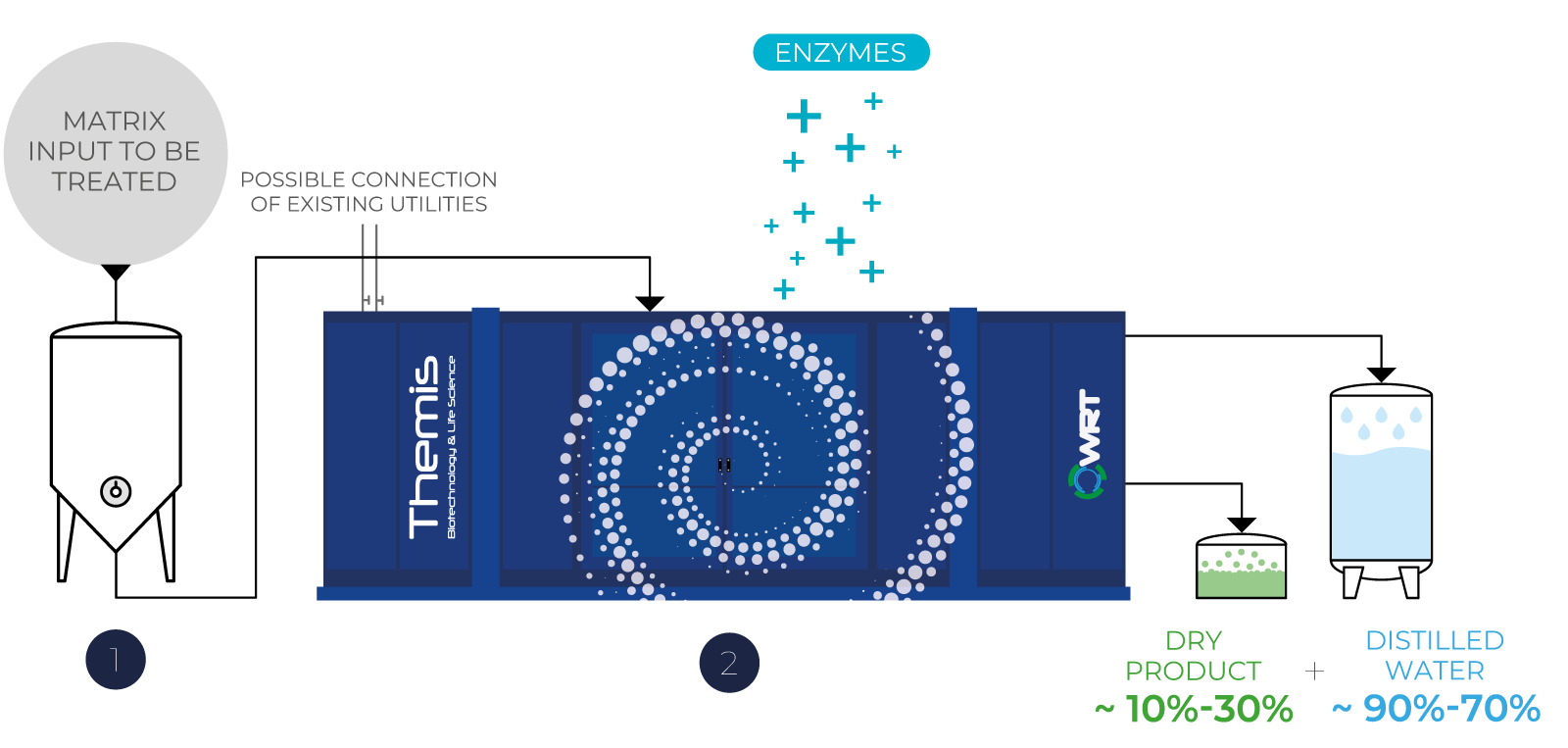

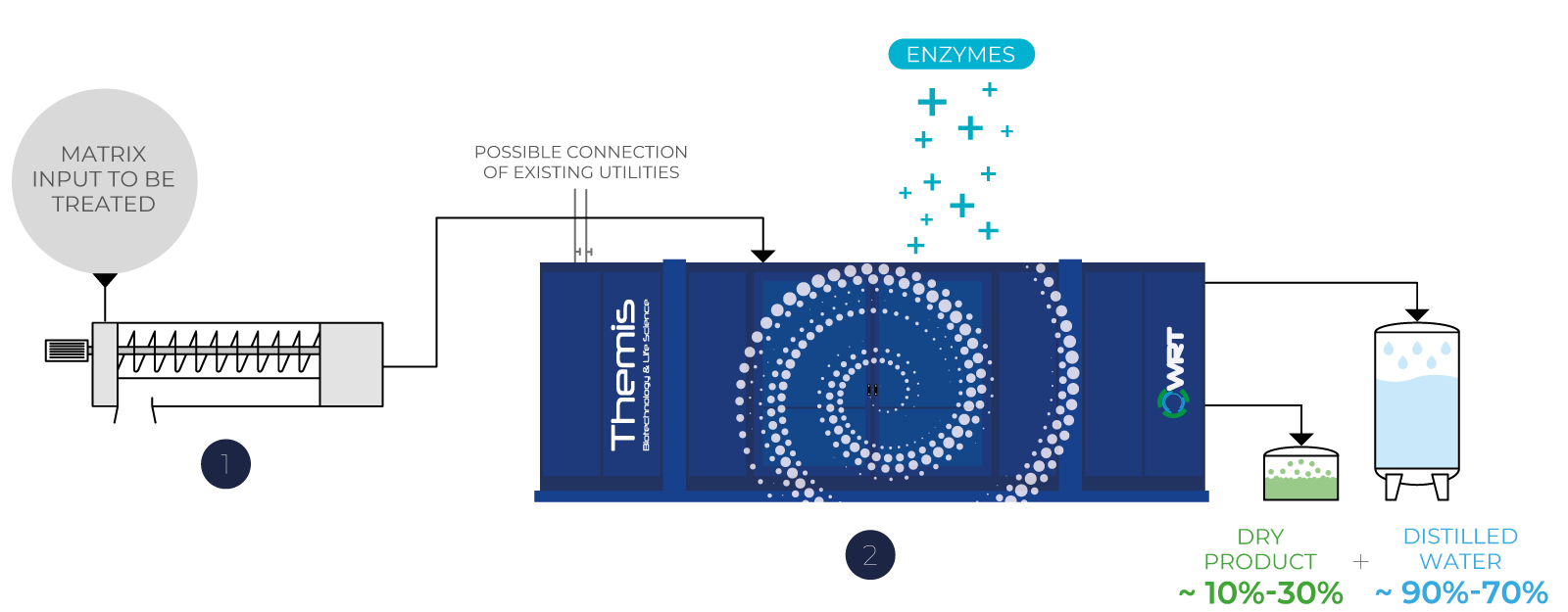

Themis WRT is a revolutionary technology designed to turn industrial waste into valuable resources. Using a multi-step process, including evaporation, drying, granulation and mixing, it reduces the volume of waste by up to 90 percent, recovering valuable materials and distilled water.

Themis WRT technology uses an innovative volumetric concentration process, ensuring sustainable and efficient waste management.

EASY INTEGRATION: Plug & Play system is quickly installed at the last phase of the production process, operating in batch or continuous mode

THEMIS WRT is at the same time an evaporator, dryer, mixer, granulator and vacuum concentrator. The system can dry different solid or colloidal matrices to the desired degree not only to reduce their volume, but also to enhance the final product.

THEMIS WRT generates sanitized and stabilized output, ensuring a high-quality end product.

THEMIS WRT is extremely versatile and can handle a variety of matrices. In addition, there is no standardized version of the machine, as the design is “ad hoc” to respond to each specific problem statement.

THEMIS WRT is managed by our “Genesis” software which allows it to be controlled even remotely. Operation is fully automatic and does not require the presence of a dedicated or specialized operator. The machine meets all requirements for obtaining tax benefits according to “Industry / Transition 5.0” standards.

THEMIS WRT operates under vacuum and requires simplified and scheduled mechanical maintenance.

The energy requirement of the machinery is limited (especially in situations of connection to energy sources already available but usually dispersed such as hot water or steam flows) so that “opex” are clearly reduced.

THEMIS WRT can be easily installed even in confined spaces thanks to its limited size and skid-mounted structure.

THEMIS WRT is the perfect application of the concept of Circular Economy: the machine transforms the original waste into distilled water that can be reused in various ways and into a treated product that can also be reused for different applications. The benefit in terms of environmental sustainability is obvious, as is the economic benefit from the zero-emission of the material to be disposed of.

THEMIS WRT operates in total absence of harmful emissions to the atmosphere, nor of sewage or unpleasant odors.

THEMIS WRT ensures a drastic reduction in the volume of waste destined for disposal (in the order of 70%-90%) thus allowing to obtain enormous economic savings relative to the costs of landfill.

Reducing the volume of waste generated also brings significant management and operational benefits.

DISTILLED WATER

~70% – 90%

DRY PRODUCT

~10% – 30%

DISTILLED WATER

~70% – 90%

DRY PRODUCT

~10% – 30%

DISTILLED WATER

~70% – 90%

DRY PRODUCT

~10% – 30%

DISTILLED WATER

~70% – 90%

DRY PRODUCT

~10% – 30%

DISTILLED WATER

~70% – 90%

DRY PRODUCT

~10% – 30%

Themis’ technological solution combines advanced filtration, evaporation, and concentration-controlled systems BY WRT, enabling recovery of treated water and optimization of wastewater management. In industrial settings, the system is set up according to a Zero Liquid Discharge (ZLD) approach, eliminating wastewater discharge and transforming residues into reusable by-products for a sustainable production model.

Membrane separation systems

Staged evaporation system

Dehydration System

Ultrafiltration (UF) Superfiltration (SF) Reverse osmosis (RO) UF and SF are used to remove suspended solids and contaminants. RO is used to refine the permeation for reuse.

For the reduction of concentrates coming out of filtration systems.

for dehydration and transformation of waste into distilled water and granulated dry material.

+ ENZYMATIC ADDITIVES (optional)

to transform the final granulate into a high added value product.

Themis WRT technology solution can treat high salinity waste, chlorinated compounds, emulsified oils and persistent organic contaminants that conventional systems struggle to manage or fail to effectively treat. The system allows to reduce the volume until absolute dryness, with the possibility of recovering salts and by-products.

Pre-treatment With staged evaporation

Drying System

Ultrafiltration (UF) Superfiltration (SF) Reverse osmosis (RO) UF and SF are used to remove suspended solids and contaminants. RO is used to refine the permeation for reuse.

for the drying of water to absolute dryness.

+ ENZYMATIC ADDITIVES (optional)

to transform the final granulate into a high added value product.

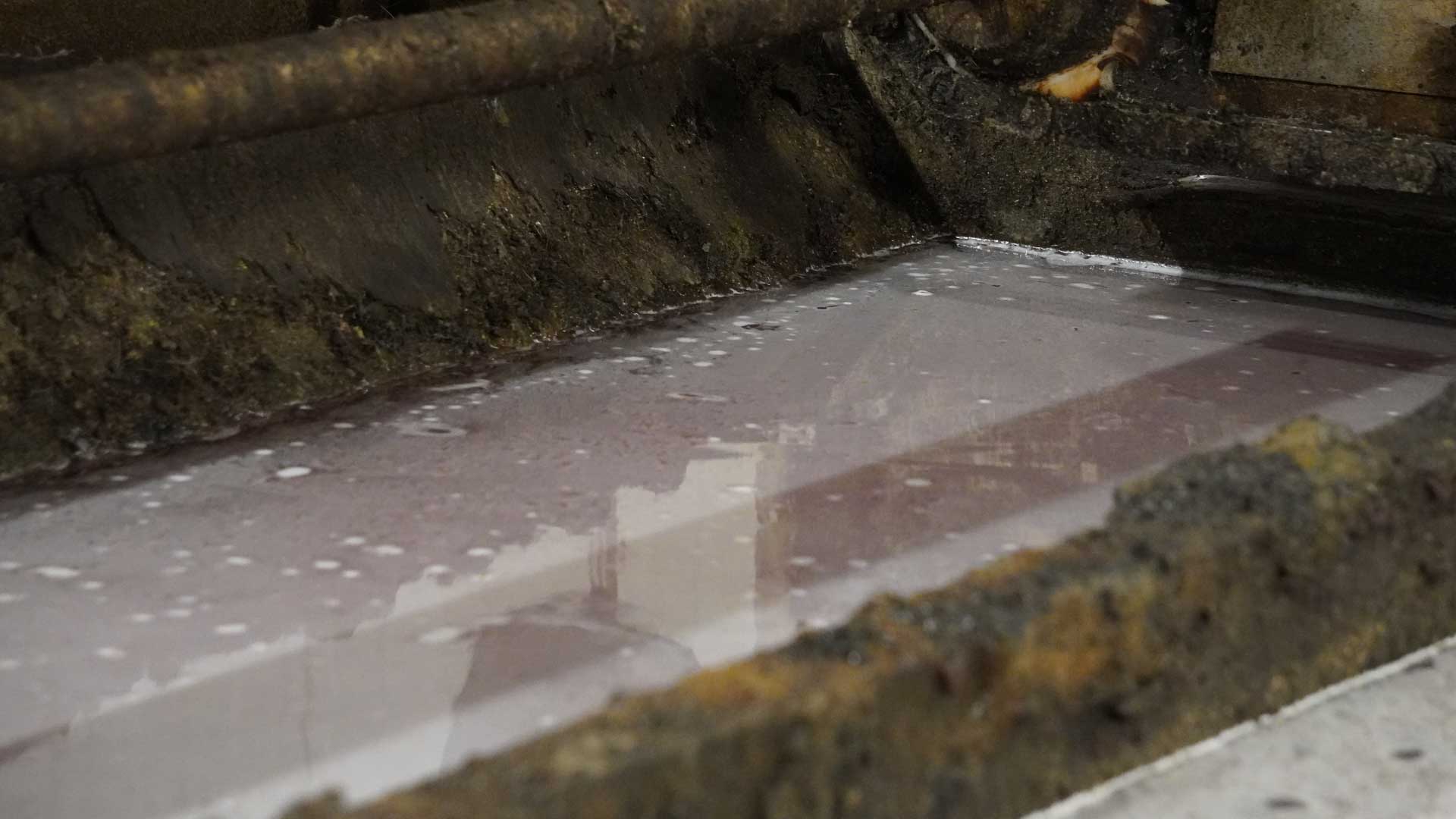

Themis WRT technology transforms sludges and industrial solid waste, reducing their volume and making them more manageable. Thanks to targeted additives, the output material can be valorised, facilitating the End of Waste process and reuse in industrial, agronomic and energy applications.

Pre-treatment with solid-liquid separation systems (optional)

dehydration system

Screw-press Spin dryers Filter presses etc.

for dehydration and transformation of waste into distilled water and granulated dry material.

+ ENZYMATIC ADDITIVES (optional)

to transform the final granulate into a high added value product.

Tailor-made solutions to make your processes more efficient, sustainable and innovative

info@themis-industries.com

©2025 Themis | P.IVA – C.F. 10272900969 | Rea MI-2518420 | Made by Ellow