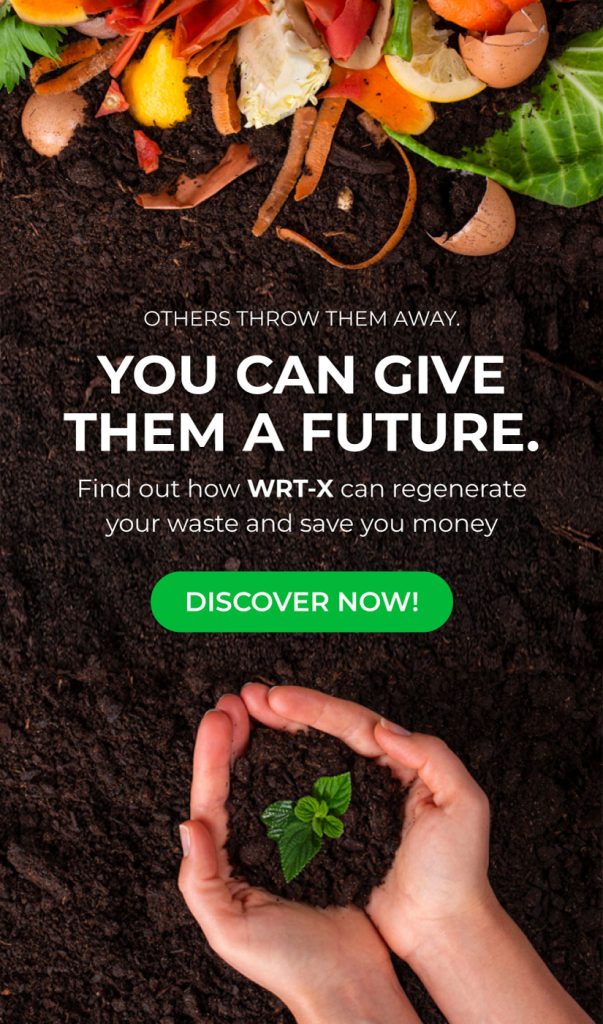

The circular economy in the fish supply chain: valorizing production waste

In the food sector, particularly in fish processing, production waste from the fish supply chain has always posed significant environmental and economic challenges. These complex organic wastes are difficult to manage, incur high disposal costs, and negatively impact the production cycle.

With the innovative WRT plant, this critical issue transforms into a concrete opportunity for sustainable innovation. The European EcoeFISHent project, funded by Horizon 2020, starts from a key question: is it possible to give new life to fish production waste by integrating it into sustainable, high-value supply chains?

The answer is yes.

The first operational results achieved at the Asdomar plant in Olbia — a company committed to sustainability — have demonstrated the process’s effectiveness. Batches of raw tuna waste were processed, producing two valuable outputs: distilled water, reusable within the production cycle or easily managed, and a dry product that is stable, easy to store, and rich in nutrients and high-value organic compounds.

Thanks to low-temperature processing technology, the organoleptic and functional properties of the material are preserved, avoiding the alterations and degradation typical of high-temperature treatments. This method guarantees a superior quality raw material, ideal for applications in the nutraceutical, cosmetic, and pet food sectors.

The benefits? Reduced storage volume, higher nutrient concentration, and new industrial opportunities. The added value? It’s not just about reducing waste, but creating a new production cycle where fish production waste becomes a resource for other sectors. A concrete example of integrated circular economy, capable of generating new supply chains, markets, and jobs.

Operational efficiency and new opportunities from day one

The use of the WRT500 plant at the Asdomar facility in Olbia represents much more than a simple technical startup: it marks the operational beginning of a new production model that effectively integrates research, technology, and sustainability.

During the first day of operation, a batch of raw tuna waste was processed, consisting of heterogeneous organic residues (heads, tails, fins, skin, meat) from the early stages of industrial processing. This type of material is traditionally difficult to manage due to its high moisture content and variable composition.

In about 6 hours of processing, the plant completed a full cycle, producing:

• a purified aqueous fraction, representing a significant portion of the initial weight, which can be reused within the production cycle or effectively treated;

• a dry powder with 94% dry matter content, stable, lightweight, easily storable, and ready for multiple industrial applications.

This first batch has already highlighted key points:

• Competitive processing times, aligned with the speed of industrial production;

• High quality of the final product, with a homogeneous structure and favorable chemical-physical parameters for high-value sectors;

• Efficient separation process that maximizes the recovery of the usable fraction even with variable inputs.

The process is flexible and adjustable based on the desired goal, both in terms of dry matter content and processing temperature, opening new possibilities for applications in:

• Nutraceuticals, thanks to the high protein content and material stability;

• Natural cosmetics, as a functional ingredient in eco-friendly formulations;

• Pet food and technical feed, where marine-derived protein products are a valuable resource.

These results confirm not only the robustness and versatility of the WRT technology but also the maturity of the vision behind the EcoeFISHent project: transforming waste into high-potential resources directly on the production line, minimizing transport, disposal, and intermediate steps.

The impact? A drastic reduction in environmental footprint and the creation of new local and scalable industrial opportunities, with immediate economic and environmental benefits.

WRT technology at the core: efficiency, flexibility, and circular vision

At the heart of this transformation is an innovative technology: the WRT system developed by Themis.

It is not just a waste treatment plant but a versatile platform for the valorization of organic and non-organic residues.

WRT system combines:

• Low-temperature thermal treatment, which preserves nutritional properties while reducing energy consumption;

• An advanced drying system;

• A fully automated structure with a digital interface and real-time process monitoring.

These features make the system:

• Extremely flexible, able to handle heterogeneous waste streams in terms of density, organic load, and composition;

• Scalable, easily integrated into different types of production facilities;

• Reliable in the long term, with low maintenance costs and minimal operational interventions.

But the real innovation goes beyond the technical aspect: it represents a paradigm shift. It is no longer just about “treating” waste but about recognizing and unlocking its potential value.

The WRT system is not simply a plant but an enabler of circular supply chains, a bridge between primary production and secondary markets.

In summary, with this technology:

• Waste is reduced;

• Resources are optimized;

• New products are created for high-value applications.

This model is replicable in many other sectors, from food to industrial, ready to become a strategic asset for the ecological transition of European industry.

EcoeFISHent: a European Project with an innovative industrial vision

With total funding exceeding 18 million euros and 34 partners from 8 countries, the EcoeFISHent project promotes an integrated industrial model that combines the blue economy (sustainable marine resources) with the green economy (circular processes and waste reduction).

Among the six circular value chains the project aims to develop, the one focused on fish waste valorization is among the most promising: a concrete response to an environmental emergency and an opportunity to generate new production chains.

One plant, one idea, one change. What was once considered waste now becomes a traceable and valuable resource. With Themis WRT technology, the circular economy is no longer just a concept but a tangible reality that creates value for industry, the environment, and society.