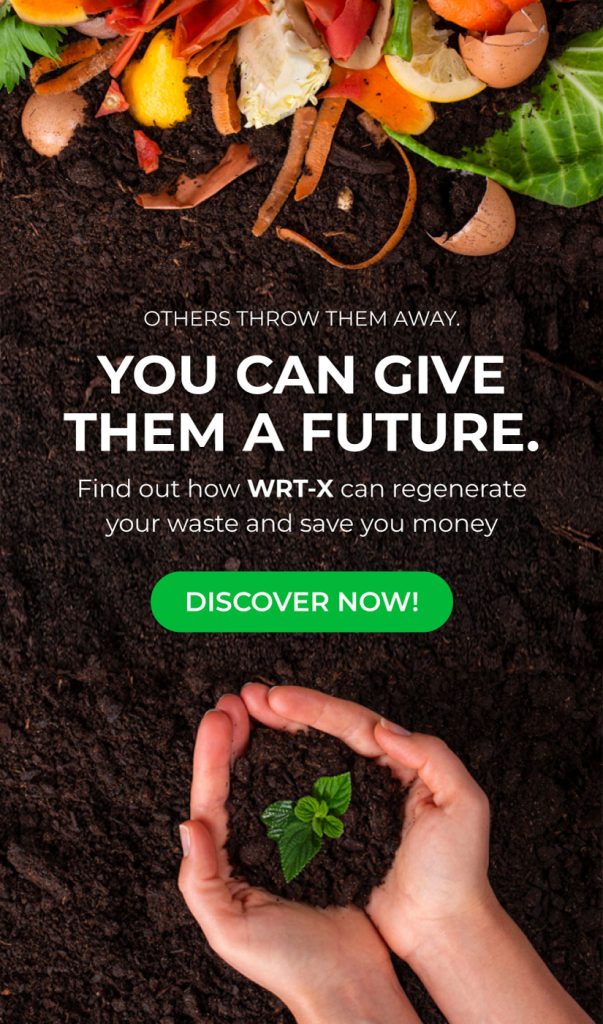

At the heart of the global food supply chain, the meat processing industry plays a crucial role. However, alongside the products intended for consumption, large quantities of organic waste, wastewater, and sludge are generated daily—posing an increasing challenge for companies, both environmentally and economically.

When handled with traditional solutions, this waste leads to high costs, environmental impact, and potential reputational risks. In a context where sustainability is no longer optional but a competitive necessity, we need to radically rethink how waste is managed.

The limits of conventional waste management

In most meat processing facilities, waste is separated, stored, and later sent for disposal—whether to landfills or incineration plants. This model presents three major issues:

- High operational costs related to transportation, disposal, and wastewater treatment

- Environmental and hygiene concerns, such as odors and water contamination

- Little to no recovery of by-products, which are seen as mere waste rather than as a potential resource

Meanwhile, evolving European and international regulations are pushing companies to drastically reduce waste generation and adopt circular production models, where waste becomes raw material once again.

The Innovative Answer: Themis WRT

This is where Themis WRT – Waste Recovery Technology comes in: an innovative solution designed to transform waste from meat processing into high-value, reusable resources.

Themis WRT is more than just a waste treatment system. It’s an integrated technology combining dehydration, distillation, and enzyme-based biotechnologies, designed to convert solid and liquid waste into secondary raw materials that can either be reused in-house or sold into other industries.

How the Process Works

- Pre-treatment: Organic solids (bones, fats, tissues) and liquids (sludge, wastewater) are collected and separated

- Dehydration: Moisture is reduced by up to 80%, cutting down volume and odors

- Biotech activation: Enzymes and active microorganisms accelerate and optimize the material transformation

- Distillation: Clean water is extracted and made reusable for industrial processes

- Final outputs:

The result is a truly “zero-waste” system that drastically lowers waste volumes and disposal costs, minimizes environmental impact, and generates new streams of value.

Turning Waste into a Resource

The core idea behind WRT is intelligent transformation. It’s not just about recycling—it’s about value creation: extracting economic and operational benefits from what would otherwise be discarded.

Some practical outcomes that WRT delivers:

- Reused distilled water, reducing consumption and utility costs

- High-density dry granulate, usable as fuel or fertilizer

- Up to 80% waste volume reduction

- Odor elimination, improving both workplace and community environments

Every Themis WRT plant is customized. The process begins with a deep analysis of the client’s specific needs to determine the best possible technological setup—aimed at maximizing ROI and minimizing payback time.

The Themis team works closely with companies to integrate the system seamlessly into their existing operations, optimizing layouts, resource use, and workflows. But the value doesn’t stop at installation—training, support, and ongoing performance monitoring are part of the package.

Sustainability as a Competitive Advantage

Today, sustainability is not just a regulatory box to tick. It’s a strategic business driver. Companies that invest in green technologies not only comply with environmental laws—they gain a competitive edge: strengthening their brand reputation, attracting ESG-conscious investors, earning environmental certifications, and often accessing public incentives and green funding.

WRT enables all of this by bringing practical, scalable solutions to the industrial transition.

Time to Transform!

Like many other industrial sectors, meat processing now has a unique opportunity to evolve into a cleaner, more efficient, and circular production model.

Themis WRT is not just a technical solution—it’s a transformation strategy. For waste. For businesses. For the industry as a whole. For waste. For businesses. For the industry as a whole.